Dear readers, With the launch of e-newsletter CUHK in Focus, CUHKUPDates has retired and this site will no longer be updated. To stay abreast of the University’s latest news, please go to https://focus.cuhk.edu.hk. Thank you.

Fixing a Loose Screw

Qin Ling experiments with bioactive implants

It was through painful personal experience that Prof. Qin Ling first got interested in improving the way that doctors fix difficult fractures. But a fateful day on the ski slopes led him to a lifelong interest that he hopes will lead to improved surgical implants for all.

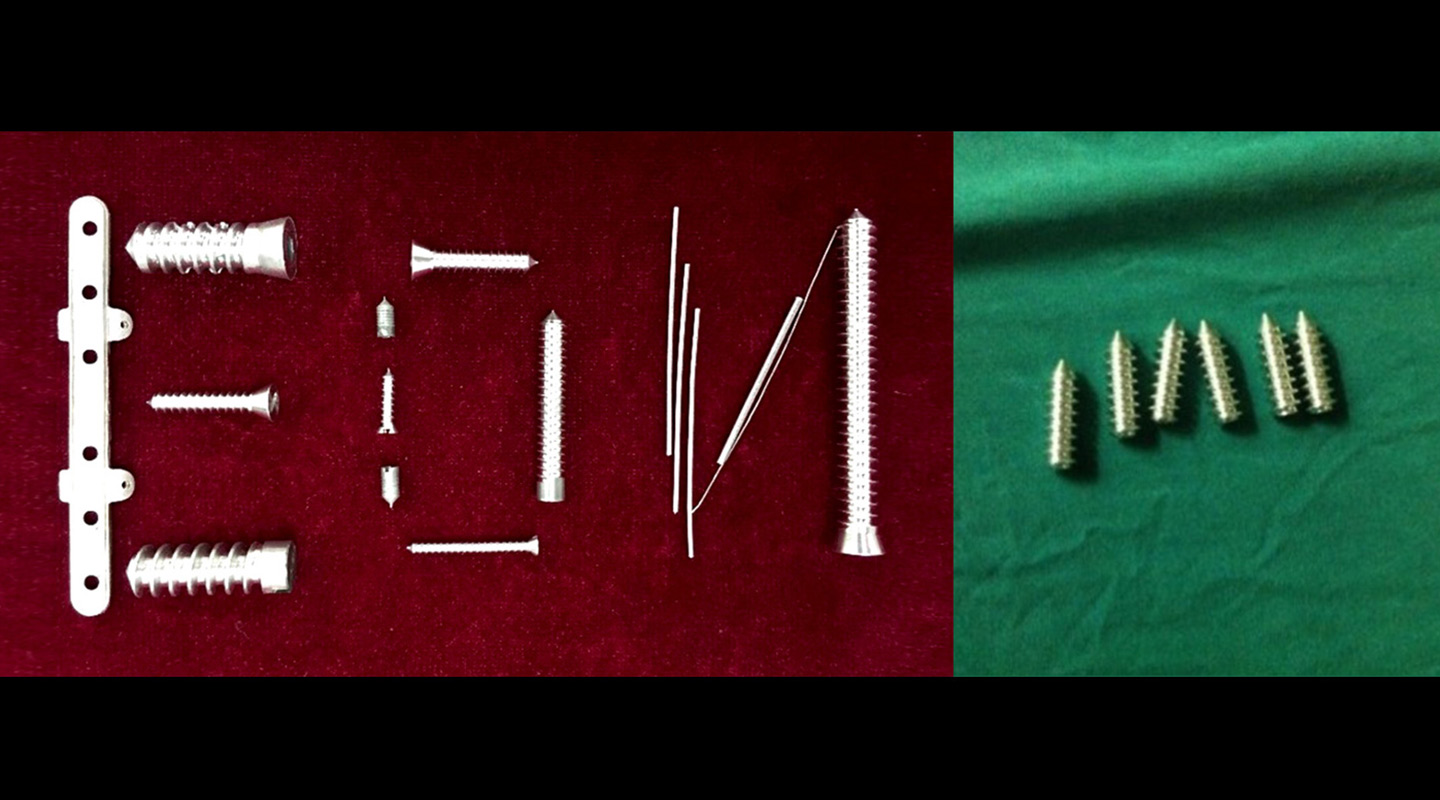

Instead of the permanent titanium plates or screws used now, Professor Qin’s experimental implants simply dissolve within the body, reducing the risk of infection or the need for removal. That’s because they are made of magnesium rather than the hard metal that’s currently used.

Magnesium is a micronutrient that the body needs to consume regularly, and is present in our diet. So as well as dissolving naturally, the new orthopedic implants have a secondary benefit in that they serve as a supplement of sorts to the body’s natural function. Magnesium is a ‘bioactive’ implant, whereas titanium or steel are ‘bioinert.’

Professor Qin may not have happened down that path at all, were it not for a life-changing experience. He was one of the earliest participants in competitive skibob races, skiing contests where riders direct a tricycle-with-skis down the slope as fast as possible. The new federation promoting skibob as a contest invited participants from as many nations as possible to take part.

Professor Qin was studying for his doctorate at the German Sport University in Cologne at the time, and gladly accepted the invitation to race a skibob. He participated in three world-championship races, but met his match in the form of a black-rated piste at the Swiss resort of Davos.

He was unable to turn quickly enough in the race and ended up careening off-piste. In the resulting crash, he fractured his cheekbone in two places. He jumped at the chance when doctors said they could rejoin the bones in his face with a stainless-steel implant.

‘When people get injured they are happy to be operated on as soon as possible,’ Professor Qin says.

But within a year, his doctors advised him that the wire join would have to be removed. The worry was that micro-movements around the eye socket could ultimately lead to infection. To have to suffer through a second major surgery on his face was a devastating blow. ‘The psychological burden is greater than the financial one,’ he explains.

His experience led him to study fracture repair. Ultimately, he began working with magnesium as a metal to help secure fracture sites.

Magnesium does not have the strength of permanent metallic implants such as titanium. That actually proves an advantage since the bones involved gradually strengthen around the join site. With a titanium implant, the body learns to rely on the metal for stabilization, and the bone does not regrow as well.

Magnesium is also a co-factor in around 300 enzyme reactions in the body. Found in green and leafy vegetables, nuts such as almonds and cashews, soy milk and whole grains, the metal leads to better bone strength in those that consume it, as well as helping with muscle growth and to protect the nervous system.

Its use is not new – it featured a century ago in treatments in Europe. What is new, though, is the purity with which the metal is now produced. Even a decade ago, manufacturers were happy if they achieved 99% purity. But that still left something to be desired for surgical uses. In the last 10 years, the achievable purity has improved to 99.99%.

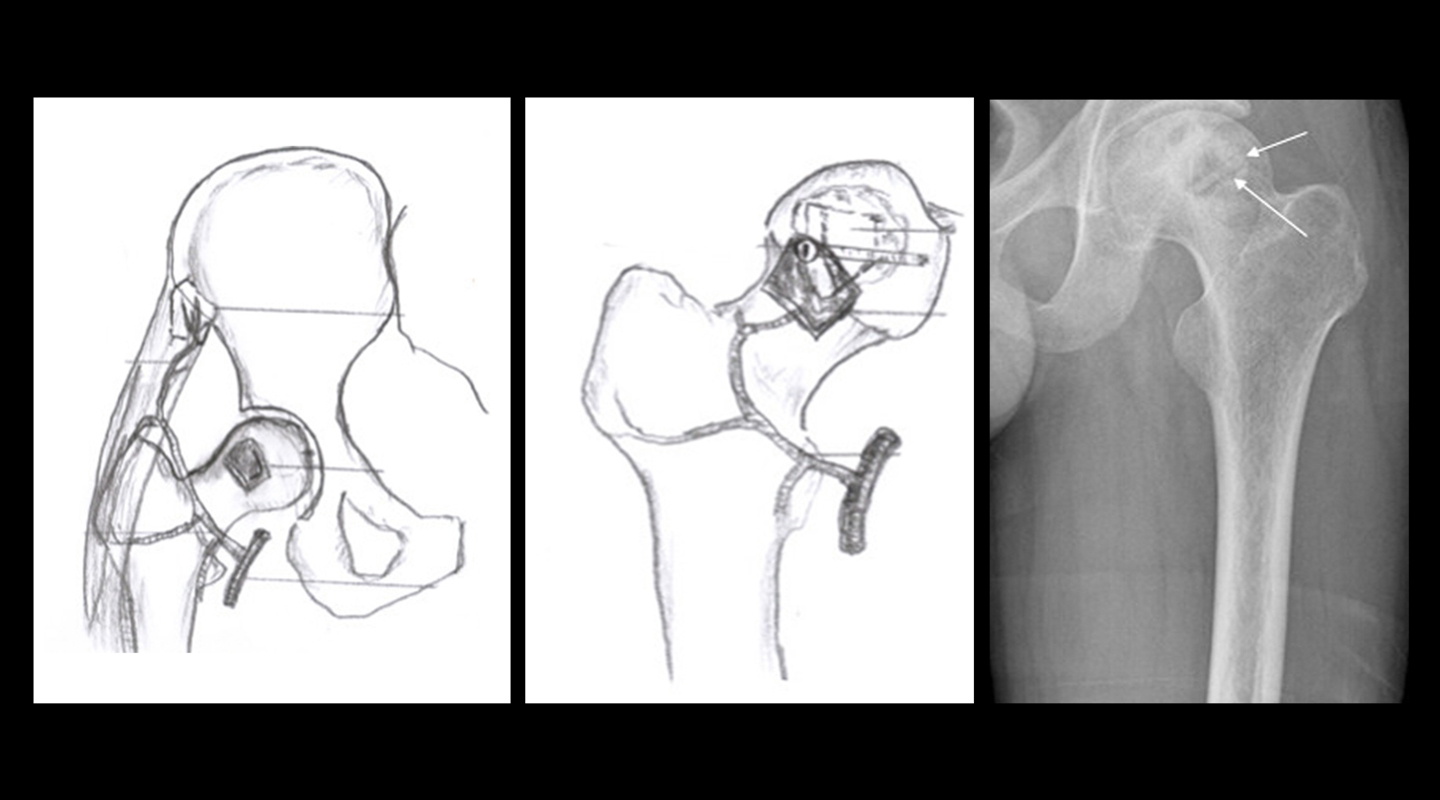

Working with hip injuries in particular, Professor Qin’s team has developed a magnesium screw that dissolves entirely within two years, aiding in the bone formation around the join site in the process. They reported those findings last year in the journal Nature Medicine. His paper demonstrating good results in the fixation of magnesium screws to prevent joint collapse has appeared in Biomaterials, another top journal.

Professor Qin is the Director of the Musculoskeletal Research Laboratory as well as the Bone Quality and Health Centre at CUHK, on top of being a professor in the Department of Orthopaedics & Traumatology. Besides hip injuries, which are particularly dangerous for older patients since the patients often develop complications from other infections while in hospital, Professor Qin has also experimented with the use of magnesium implants to help heal tears of the anterior cruciate ligament.

ACL tears are particularly common with younger patients, between the ages of 15 and 25. It’s difficult to suture the ligament back into place, often requiring doctors to drill a hole into the knee to fix a graft in place.

With a normal metal screw, there is the risk that the constant wear and tear of the knee eventually results in the widening of its insertion tunnel. A magnesium screw, by contrast, stimulates bone growth around its insertion site, eventually dissolving in place.

Professor Qin has already established the efficacy of magnesium implants in rats, rabbits and goats. Together with a collaborator at a hospital in Dalian in northern China, they have now successfully introduced magnesium screws in some 200 human patients, in a single-centre trial.

The bipedal stance of humans creates different load-bearing issues in humans compared with quadrupeds. Other doctors are also using the same implants in experimental treatments in Europe. With the China Food and Drug Administration currently evaluating their use for multicentre trials, Professor Qin hopes magnesium implants will soon be introduced in his homeland and such technology will contribute to the research and development of orthopaedic devices in Hong Kong.

Professor Qin is also working with companies in southern China to commercialize the magnesium implants. A collaborative effort has led to a manufacturing site being set up in Dongguan in Guangdong Province just across the border from Hong Kong, to make hip screws.

‘Magnesium is not a new material, but we have found a new application on the medical side,’ Professor Qin explains. ‘It’s a material that is good for the body, and it’s part of the body.’

By Alex Frew McMillan

This article was originally published on CUHK Homepage in Feb 2018.